Cane unloader trolley with Bridge |

|

Our is a specially designed cane unloader trolley which works more than 150% in two motion also three motion, also it's operation is noiseless & maintenance free.

Till today we had successfully Commissioned more than 50 Nos. of various capacities with different operations & types ranging 5 M.T. SWL to 15 M.T. SWL capacities with robust design. |

|

| |

|

Swing Type Leveller |

|

This is the Modern Technique to achieve higher P.I. at leveller station which will helpful to reduce excess load on mills. In this techniques leveller knife is directly contact with cane more than 30% to 40% of fixed type leveller due to that at leveller station P.I. can achieve upto 70+ in our design only. We can modify existing fixed type leveller into swing type & pay back of this unit is not more than 60 days working of unit. |

|

| |

|

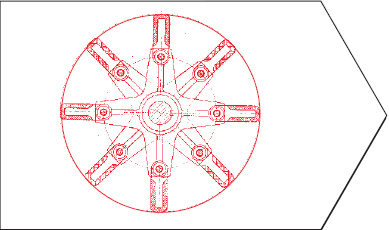

Swing Type Fibrizor |

|

Fibrizor is the most important unit in sugar industry & it is the key to reduce Millin Losses.

Ours is a special designed Fibrizor which is very easy to installation on existing cane carrier also it is maintenance free & easy to operate.

Anvil Plate is the heart of fibrizor, our designed anvil is upto 165 to 180 degree wrap angle. Hubs

are specially designed for itself balancing & rotor is placed such as to provide maximum grating arc to avoid uncut cane. Our designed fibrizor P.I. can be achieved upto 85+.

In existing fibrizor modification can be done to achieve P.I. 85+ with anvil plate modification as per our design.

|

|

| |

|

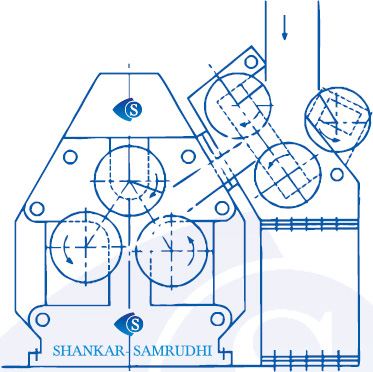

Shankar - Samrudhi Six Roller Mill |

|

We have great pleasure to introduce our Shankar - Samrudhi Six Roller Mill which is Super Structured Mill. This Mill is Free Floating & a example of Modern Technique, when it works as a 'O' Mill the Primary Extraction can be achieved upto 75 to 80 which is the very higher side in India.

Features:

- Shortest Presssure Chute.

- In regular practice rollers can work without Re-Shelling more two Crushing seasons as compare to other Conventional Mill Rollers.

- Due to more compression P.E. can be achieved upto 80

- Required Power is less as compare to other Conventinal Mills

- Easy to assembly & dismantling

- Due to robust design crush rate is 50% more as compare to other Conventional Mills.

- Easily work at Imbibition % water upto 280to 300% on fibre.

- Due to Planetary drive & rope coupling there is no any chance to misalignment.

|

|

| Our Shankar - Samrudhi Mill is designed to handle very high crush rate with maximum Extraction. Due to unique arrangement of Hydraulics Top Roller can lift freely which resulting in better Extraction & less Power consumption. Due to Modern Technique in hyd. System there is not any single chance of leakages. Top Roller as well as Bottom Roller bearing are of Gun Metal so there is no single problem at higher crushing rate. Headstock design is so sturdy as comparing to other mills & work at higher crushing rate. There is higher Compression in mills resulting in low Moisture also less Bagasse Pol at higher crushing rate. Mills can be supplied from 18"X26" to 52"X104". |

| |

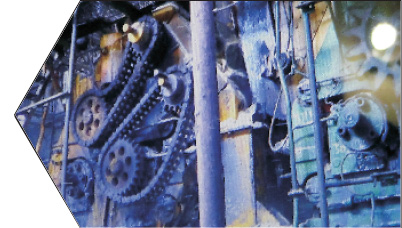

TRPF |

|

To improve performance of conventional three roller mill Toothend Roller Pressure Feeder is added to mill & this mill is called five roller mill. Our designed TRPF system is suitable for any mill & can be easily installed to all types of mills. It provides smaller contact angle, small length of pressure chute & low power consumption. TRPF can be driven by chain drive on existing mill Top & Feed roller, also by separate drive method by using Planetary drive. |

|

| |

|

Understanding the customer requirement & efficiently designing Boiling House equipments play a major role in minimizing the steam & power consumption with optimum throghput. Here Samrudhi Engineers come with unique thermodynamically designed equipments. These equipments had benefited the Sugar Industry. Our innovative design works on minimum power consumption. These designs had cut down requirement upto 40% similarly special vapour bleeding system along with special vapour bledding system along with pressure stabilization had resulted steam consumption upto 40% to 45% on cane. |

| |

|

Evaporators |

|

Our conventinal Evaporators, Semikestners incorporate many unique design features which make the system readily acceptable to the Sugar Industry.

Features

- Special Vapour Bledding system resulting Steam Saving.

- Increasing Capacity of Boiling House.

- Reduced Inversion Losses.

- Required space is less.

- Scaling problem is less due to high velocity.

- No Re-circulation Pump so Power saving is achieved.

- Easy to clean.

- No entertainment of juice with vapour due to better design of 'Save alls'.

- Pressure of outlet vapour increased resulting better Pan Boiling.

|

|

| |

|

Low Head Pans |

|

Features

- Capacity of Low Head Pans are 25% more than conventional Pans.

- Strike rate increases upto 30% due to Hydrostatic Head.

- Lower pressure vapour can be used for pan boiling.

- Crystal is so uniform.

- Low Hydrostatic Head implies low boiling point elevation & less damage to sugar crystal.

- Discharge valve of Hydraulically/ Electrically/ Pneumatically can be fitted with provision for manual operation.

|

|

| |

|

Crystallizers |

|

The Batch Crystallizers made available by us are known for high quality & performance. Our Batch cooling Crystallizer are must for any sugar industry. As well as our company presents Superlative Vacuum Crystallizer in a Sugar Industry. Our circulating Vacuum Crystallizer is high performing & used for Crystallisation. |

|

| |

|

Juice Heater |

Normally juice heater consists of an assembly of tubes. The juice circulates through the tubes & the vapour outside them. Suitable headers force the juice to pass a certain numbers of times from bottom to top and from top to bottom of the heater by restricting the juice each time to a few of the tubes. We manufacture Conventional types Dynamic type & Vapour Line Juice Heaters. |

|

| |

|

Samrudhi Make Single Jet Cooling Tower |

|

We have great pleasure to introduce ourselves that we have a Team of Design Engineers working in Sugar Industries also we have a well equipped workshop at Bhosari MIDC, Pune. In last ten years we designed some specail jobs which helps to improve crushing capacity, reduce losses & save power also done some special Patented Modifications in existing machinery to achieve higher efficiengy of plant.

In sugar factory we observed that during crushing season lots of hot water(Condensate) goes wastage to ETP due to that excess load born on ETP. It is directly effect on Environment Cycle.

We studied this problem in detail & we had designed Samrudhi make Single Jet Cooling Tower for excess condensate, which is totally different of any other cooling tower. This Cooling Tower works on Thermodynamic Principle. In this system excess condensate of any temperature transferred to cooling tower & get cold water of ambient temperature within fraction of second. This cold water can use for Service Water Tank also Turbine cooling.

|

|

|

Our Samrudhi make Cooling Tower is working in single stage only due to that the maintenance cost of this system is zero & can be work in any season.

Advantage of Single Jet Cooling Tower

- This Cooling Tower is in single stage only so maintenance cost is zero.

- This Cooling Tower material is specially effected material so it can work at any Temperature.

- We can get cooling effect within fraction of second so there is no necessary to take cold water from outside due to that cost of cold water can be save.

Pay Back

The pay back of this system is within 15 Days working of this system. So, this system is totally beneficial & cost effective for Sugar Plant. |

| |

|